Behind the scenes of UI/UX design in digital manufacturing

The UI/UX experience plays an important role in manufacturing because, it can profoundly impact the user’s satisfaction.

User-centric UI/UX for manufacturing software

By alleviating frustrations, enhancing a sense of productivity, and offering greater flexibility to manage production runs, a well-designed user interface (UI) and user experience (UX) can simultaneously enhance safety measures, leading to improved overall operational effectiveness and efficiency.

In this blog, we'll explore key principles and considerations, tailored to help manufacturers of all sizes to help transform their entire production operations. Here’s what you will find:

- Comprehensive functionality

- Workflow efficiency and flexibility

- Open architecture and a strong API

First, it’s important to understand why comprehensive functionality is paramount. At this part, designers need design functionality that equips users with diverse tools necessary for their work.

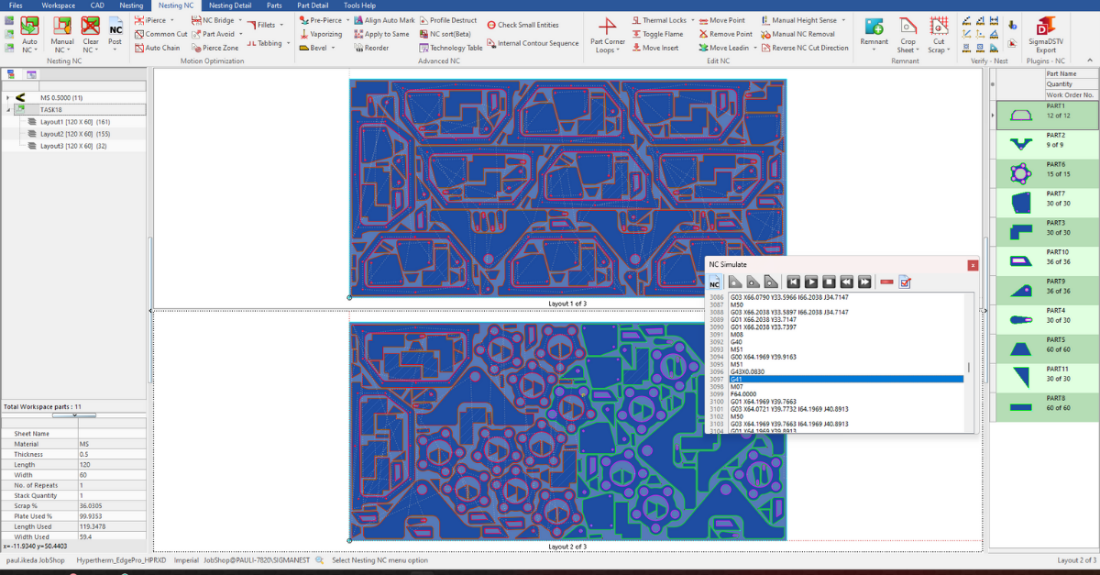

For example, CAD/CAM programming software should exceed essentials, reflecting the dynamic nature and variety that is inherent in a successful manufacturing environment. Users need to fabricate a broad spectrum of components, utilizing diverse materials, with a pressing need for speed. From simple tasks to complex challenges that test the limits of the shop, machines, and consequently, the software tools must cater to all.

Secondly, the system needs to accommodate diverse workflows, offering the flexibility of choice to reach the same destination. Just as one might choose alternative routes in a car to bypass heavy traffic, circumvent road closures, or incorporate a brief stop for a coffee, user-friendly software offers multiple avenues to achieve the same result. This flexibility not only minimizes unnecessary steps but also fosters user creativity, allowing them to apply their skills when programming complex part features or nesting parts on the material for easier offloading.

Thirdly, while the baseline user experience and functions are important, the true testament of exceptional software lies in its capacity for customization and plugins. This personalization empowers the business by enhancing the areas where the tool adds the most value. An open architecture, coupled with a robust suite of APIs, allows users or a consulting team to build on a solid foundation, further boosting the potential for business growth and innovation.

Workflow efficiency and flexibility: navigating the manufacturing maze

Designing software features for the manufacturing industry must have a focus on the end-users. It’s critical to inform them with both qualitative and quantitative insights.

Qualitative feedback is obtained through direct interactions with our customers and close collaboration with our operations teams who have extensive contact with end users. This hands-on approach allows us to hear directly from those using our software, gaining an intimate understanding of their experiences and needs.

Quantitative analysis, on the other hand, involves meticulous collection and examination of data such as usage metrics, sales numbers, and support cases. This data-driven perspective offers insight into software usage patterns, areas of growth, and potential opportunities for improvement and investment.

The ultimate goal for any new software feature is to have a transformative impact, significantly enhancing the software for the majority, if not all, of the users within a target group such as quoters or router programmers.

Also, a public forum or discussion board can also serve as a crucial platform for interactive engagement between users and a product team. Manufacturing software developers need a place to facilitate invaluable dialogue about use cases, feature development progress, and potential improvements. By making the process of planning product improvements transparent to everyone, product managers can stay updated with industry trends and changes in machine abilities.

This open, inclusive approach helps ensure that feature development is not overly influenced by a single customer's needs, which helps prevent the risk of narrowly scoped specifications.

Typical UI/UX workflow development for manufacturing

When an initial idea or feature suggestion is proposed a good first step is to gather context about the request to change your product. Find out what is driving the user to propose the suggested changes.

Is there an operational pain point or an opportunity to improve an already working process?

By validating the request, developers can filter out situations where a user might not be aware of existing functionality or there’s a different issue. Then, it’s time to do some research into existing related requests in our backlog system and the area the suggestion is based on. As with any piece of software, it is much easier to make changes in more recently developed areas compared to low-level or very old sections in the code base.

Once the UI/UX idea is accepted for development this is what the typical next steps look like:

- Discuss the specification or share a UI mockup with key stakeholders like the operations team or the technical leads in our global offices to gather feedback.

- Time to plan, test, review, gather more feedback, refine, and repeat until the backlog is ready to be assigned and planned in a sprint.

- Then a walk-in is performed. Another member of that development team will perform what is called a “walk-in” receiving a demo of the feature, performing some exploratory tests, and asking questions about what the feature should or should not do. The walk-in is critical as a vetting process to help catch minor bugs and adds polish through refinement within the development team.

- Code changes are published.

- A gambit of tests and policy checks are automatically performed, and the code is formally reviewed by another developer, usually the team’s technical lead.

- The QA team goes to work to evaluate the stability of the feature as well as test it against standard workflows and example files.

- If the test case is passed, the feature is documented by our technical writer and ready for shipment in the next release.

UI/UX seamless integrations: specialized functionalities of manufacturing software

Developers understand that users often employ products and applications in tandem with a variety of other software tools in their businesses.

Depending on an individual's role within the organization, a developer may transition between a handful or even dozens of apps throughout the workday. For this reason, we've deliberately designed our applications' user interface to echo the aesthetics and functionality of familiar applications, whether it be the mouse controls from their CAD system or the ribbon toolbar from their email client.

The echo approach allows us to lessen the cognitive load on the user and prioritize the design and implementation of intuitive controls and visually coherent interfaces, rather than emphasizing enigmatic or highly unique UI-UX designs. By embracing this strategy, even the most specialized functions within our products remain user-friendly and can be expertly navigated by every user.

User feedback plays a vital role in software development for manufacturing

User feedback is integral. Use methods such as anonymous analytics, in-app surveys, and suggestion portals to gather insights. Open, inclusive approaches help shape features that benefit the majority of users, preventing narrow-scoped specifications.

Skill gaps between users are a tricky part of manufacturing software development

Managing the skill gap between expert users and beginners is one of the trickier parts of software development. Both types of users must be able to navigate the application and do their jobs, despite their different skill levels.

Behind the scenes at SigmaNEST

Our usual strategy starts with a strong set of manual functions. It's like having a good selection of tools in your toolbox, ensuring users can get the job done.

We then build user stories to understand why users prefer certain functions for their tasks, paying attention to which features and settings they might use for the operation.

With this understanding, we start to link or merge some of these functions. While this doesn't immediately create a fully automated process, it's a step towards semi-automation – just like how a nail gun is easier and faster than a hammer but requires more skill.

Upon successfully integrating a substantial number of functions and workflows, we're equipped to offer a genuinely automated user experience.

These sophisticated abilities consider:

- The material,

- Machine presets, and

- The user's ultimate objectives

All aiming to deliver a result that necessitates minimal subsequent intervention. We're continuously driven by our customers striving for highly automated environments. Their aspirations persistently push us to expand our horizons, inspiring us to explore the realm of what's truly possible in automation.

Artificial Intelligence of Things: advanced manufacturing software

Incorporating AI and IoT into UI-UX is the means to improve human-machine interactions. Analyzing historical data, predictive modeling, and IoT sensors enhances the manufacturing experience.

As shops become more digitally connected with orders, machines, and people it becomes increasingly valuable to analyze historical data and build predictive models.

AI can be paired with performance metrics to look out for factors that might cause machine downtime, part defects, late orders, or inefficient operations.

There’s likely a similar benefit to be realized in manufacturing software – where users can ask observational questions like, “What’s the status of order 123?” or analytical questions that require the AI to do some calculations like, “Do I have enough of material A to cut all open jobs?” A lot of time can be saved if users aren’t forced to burrow into the software and locate or calculate this information themselves.

UI/UX designing customizability and security with a user-friendly interface

Balancing customizability with a user-friendly interface is important for shops that have unique workflows. Building adaptability into the tools and features helps to cater to diverse workflows. If you’re a UI/UX designer working on manufacturing solutions keep customization in mind for users, and safeguard sensitive and administrative options with permission levels for users.

Digital manufacturing solution designers build integrations for plugins to enhance or even automate functionalities, for example, enterprise resource planning (ERP) platforms or Business Intelligence (BI) tools.

UI/UX security standards for manufacturing software

The security and compliance landscapes are constantly shifting as technologies and threats advance. Therefore, it’s important to invest in educating developers. Allocate time and budget to send designers to training courses covering UI/UX security and compliance topics. By keeping updated on the latest trends, you ensure the latest standards and practices are designed into the software interfaces and connection points to ensure minimal exposure.

UI-UX success in manufacturing

Having a connected shop ecosystem via a suite of apps is convenient for manufacturing teams. Because on a daily basis a variety of processes are taking place at the same time, from machine programming and scheduling to transporting machined parts to the next process point.

One example is a feature we created at SigmaNEST, called the “Swap Sheet” button. This feature was created because, while a programmer may create a program intended for SheetA, the operator might end up using SheetB.

In another example, a placeholder sheet might be used by a programmer, only to be updated by the ERP system based on incoming material shipments. Both examples highlight a common reality in workshops: operations don't always proceed as initially outlined by the programmer.

The UI-UX our Swap Sheet feature revolves around three primary principles:

- The same “Swap Sheet" button can be found in SigmaNEST, the CAD/CAM programming application, and Color Offload, the app that facilitates machine-side offloading, which empowers both the programmer and the operator. This button allows them to quickly select their desired sheet through visual graphics, sheet dimensions, and other attributes.

- SimTrans, our transaction-based ERP data synchronization tool, incorporates this feature, granting the ERP system the capability to interchange any sheet, especially those recently added.

- This flexibility is also extended via our API. It enables customers to custom use plugins and apps, perhaps integrating barcode scanning or automating specific tasks like always swapping sheets with a special naming format.

By enhancing accessibility and user-friendliness, Swap Sheet can significantly boost your efficiency without requiring employees to start over. It also ensures that the solution seamlessly aligns with and adapts to their unique workflows.

In this brief glimpse behind the scenes of UI/UX in developing manufacturing software, you’ve seen the step-by-step UI-UX design and development with examples. As a designer in manufacturing digital solutions, remember it’s important to research, map, and test user experiences. This is how you can ensure factories run like well-oiled machines. As technology evolves, so do innovations, it’s important to stay well-educated on the industry trends.

You can gather further insights about making digital manufacturing solutions simple for humans to work within these similar guides.