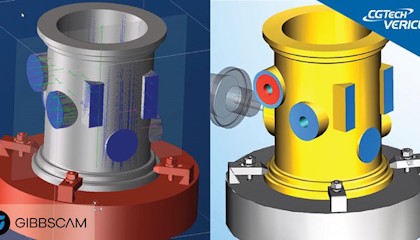

GibbsCAM® and VERICUT® together prevents shop floor errors

Benefits of using the CGTech VERICUT integrated with GibbsCAM.

Understanding the benefits of GibbsCAM VERICUT interface

GibbsCAM to CGTech VERICUT (GCV) tightly integrates the two programs to help gain the most accurate and efficient Numerical Control (NC) programs possible. It makes verifying NC programs and simulating CNC machines a more efficient process.

All stock, fixture, and design geometry are automatically transferred to VERICUT in the correct orientation, along with the NC program, tooling, machine and control data, and other simulation parameters.

Benefitting multiple departments, VERICUT shortens cycle times, optimizes programs, and enhances precision, saving costs and reducing scrap. Its reviewer tool visualizes 3D machining steps, uncovering potential issues, and optimizing workflows.

A smart solution for efficient production, VERICUT is a crucial tool for modern manufacturing.

Here is an example of launching this interface and a workflow example of VERICUT making the connectivity between CAD/CAM and tool management seamless.

GVC streamlines the numerical control program verification process

The GibbsCAM manufacturing file contains all the essential manufacturing data required for a VERICUT session.

Once you have a VERICUT session open with the GibbsCAM manufacturing data pre-loaded and ready to stimulate the CNC machine, you select the play button, and VERICUT processes the NC programs.

How to identify an error during a GVS process simulation?

When an error is detected by VERICUT you can quickly identify the error and the corresponding line in the NC program which caused it, and then continue to process the NC program.

What happens once the NC program has run the GVS?

Once the NC programs run you can inspect the cut part. To do this, you simply use Auto-Diff to compare the cut part to the design model.

With the current settings Auto-Diff will report any gaps deeper than a 0.005 gouge, displayed in red and overlay the gouges in a translucent design model.

After inspecting the cut part, you can then generate a shop document. This document's look and feel can easily be modified to fit your company look and feel.

The benefits of GVC to VERICUT interface.

The software benefits various manufacturing departments, shortening cycle times, preventing errors, and saving costs. This integration enhances tool life, reduces scrap, and ensures precision. Its reviewer tool aids machine operators by visualizing machining steps in 3D, uncovering potential issues. This smart solution streamlines manufacturing workflows for an efficient and effective production.

However, the capabilities of VERICUT extend beyond its fundamental functions.

For example, the Auto-Diff feature undertakes a thorough comparison between the intended component design – comprising solid surfaces or point models – and the outcomes of the simulation. This meticulous assessment brings to light any disparities or deviations, streamlining the process of detecting potential issues that might arise between the initial design and the final machined component. To facilitate ease of use, an interactive error list aids in the identification of possible complications, fostering a seamless alignment between the design phase and the actual machining process. Below is an overview of the benefits of this integration.

Accuracy

GCV ensures that all stock, fixture, and design geometry are transferred to VERICUT in the correct orientation. This accuracy enables users to evaluate the machining process with confidence, minimizing the risk of errors and collisions.

Efficiency

The integration between GibbsCAM and VERICUT streamlines the verification process, saving time and effort. With GCV, users can quickly generate and run NC programs, reducing the need for manual data transfer and potential errors associated with it.

Realistic Simulation

VERICUT advanced simulation capabilities allow users to visualize the machining operations in a virtual environment accurately. This realistic simulation helps identify potential issues, optimize toolpaths, and enhance overall machining efficiency.

Error Detection

VERICUT powerful algorithms analyze the NC programs for potential errors, collisions, and inefficiencies. By running a VERICUT session using GCV, users can identify and rectify issues before transferring the programs to the CNC machines, minimizing costly mistakes, and reducing downtime.

Learn more about: